Editorial

Here we are so excited to share the insight we have gained, the questions we are asking at the REV office and interviews we have conducted to learn more ourselves about how we all live more naturally and harmoniously. This section is full of articles concerning everything to do with a sustainable lifestyle and conscious living.

Fashion

See All Fashion EditorialsLifestyle

See All Lifestyle EditorialsTravel

See All Travel Editorials

Beauty

See All Beatuy Editorials

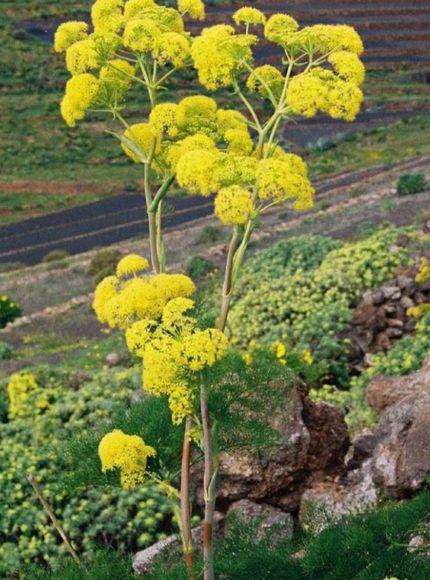

Food & Garden

See All Food & GardenWellness

See All Wellness Editorials

Home

See All Home

Parenting & Baby

Sell All Parenting & Baby

Environment

See All Environment